Encyclopedia of component selection specifications

Therefore, the correct and effective selection and use of electronic components is an important task to improve the reliability of electronic products. The reliability of electronic components is divided into inherent reliability and use reliability. The inherent reliability is mainly guaranteed by design and manufacturing work, which is the task of the component manufacturer.

However, failure analysis data at home and abroad shows that nearly half of the component failures are not due to the inherent low reliability of the components, but due to the improper selection or incorrect use of the components by the user. Therefore, in order to ensure the reliability of electronic products, the selection and application of electronic components must be strictly controlled.

一. General rules for material selection

1. The selected devices follow the company's normalization principle, and choose as few types of materials as possible without affecting the function and reliability.

2. The material whose "preferred grade" is "A" in the material code library is preferred.

3. Preferred devices that are in a growing and mature life cycle.

4. Select the devices that were born and dropped to go through the special approval process.

5. Carefully select devices whose life cycle is in decline, and prohibit the use of discontinued devices.

6. For power devices, packages with low RjA thermal resistance and greater Tj junction temperature are preferred.

7. It is forbidden to select devices with a package size smaller than 0402 (inclusive).

8. Anti-ESD ability is at least 100V, and anti-static measures are required to be designed.

9. The MSL (moisture sensitivity level) of the selected components cannot be greater than level 5 (inclusive).

10. The airtight vacuum packaging model is preferred. If the MSL (moisture sensitivity level) is greater than level 2 (inclusive), airtight vacuum packaging must be used.

11. The models of tape and reel packaging and pallet packaging are preferred. If it is a device with a moisture sensitivity level of grade 2 or above, a disc-shaped plastic braid packaging is required, and the disc-shaped plastic braid must be able to withstand a high temperature of 125°C.

12. For key components, there are at least two brands of models that can be substituted for each other, and some also consider program-level substitution.

13. The materials used are required to meet the requirements of anti-static, flame-retardant, anti-corrosion, anti-oxidation and safety regulations.

二. Selection rules for various materials

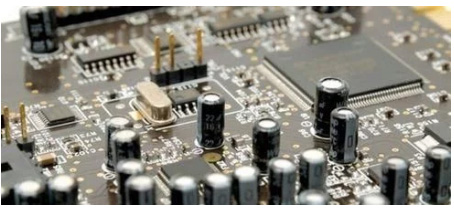

General rules for chip selection

1. Leaded BGA solder balls are preferably Sn63Pb37 alloy, or SnPb alloy with high lead (lead content ≈85%). SnAgCu alloy is selected for lead-free BGA solder balls.

2. Lead wire SMD and integrated circuit devices, the lead wire metal material should be copper, copper alloy, valve alloy, 42 alloy material, the surface alloy coating is uniform, the thickness meets the relevant standard (4~7.6μm), the coating Must not contain metallic bismuth. Tin-lead lead plating: SnPb; Lead-free lead plating: Preferred: Matte-Sn, SnAgCu, Ni/Au, Ni/Pd/Au; Sn plating: For pure Sn plating, the thickness of Sn plating ≈7.6μm (plating Process), or ≈2.5μm (melting process after electroplating), or ≈5.1μm (immersion tin process), or ≈0.5μm (electroless plating process); barrier layer Ni: thickness ≈3μm; SnCu coating: SnCu coating thickness ≈3μm ; Ni/Pd coating: Pd coating thickness ≈ 0.075μm, Ni coating thickness above 3μm; Ni/Pd/Au coating: Ni thickness ≈ 3μm, Pd thickness ≈ 0.075μm, Au thickness in 0.025~0.10μm

3. Use Taiwanese CPU and power chips carefully.

4. It is forbidden to use QFN packaged components. If only QFN packaged components can be selected, it must be reviewed. Any chip in the QFN package must be approved by the first-level leader of the company before it can be used.

5. For IC, chip package devices with a pin pitch of at least 0.5mm are preferred.

6. SMD packaged devices are preferred, and DIP packaged devices are carefully selected.

7. Try not to use BGA packaged components, you have to use them. If BGA is selected, the BGA ball pitch must be greater than or equal to 0.8mm, preferably greater than or equal to 1.0mm. And try to use the leaded BGA ball device model, and use the leaded soldering process.

8. It is forbidden to select a CPU that does not support online programming.

9. Try not to use Samsung chips.

Resistance selection rules

1. 10 series, 12 series, 15 series, 20 series, 30 series, 39 series, 51 series, 68 series, 82 series are preferred for resistance value.

2. SMD resistors are preferably 0603 and 0805 packages, and packages below 0402 are forbidden.

3. The pin resistance is preferably 0.25W, 0.5W, 1W, 2W, 3W, 5W, 7W, 10W, 15W.

4. Regarding the temperature drift of the resistance, the temperature drift of the J mode cannot exceed 500ppm/℃, the temperature drift of the F mode cannot exceed 100ppm/℃, and the temperature drift of the B mode cannot exceed 10ppm/℃.

5. Metal film resistors 1W and above are prohibited, and metal film resistors above 750k are prohibited.

6. The axis type of power resistance above 7W is prohibited.

7. Choose the potentiometer carefully. If it is unavoidable, use multi-turns and use BOURNS for the brand. The electronic potentiometer operates in accordance with the chip selection specification.

8. The resistor brands are preferably YAGEO, MK, and Bedis.

Capacitor selection rules

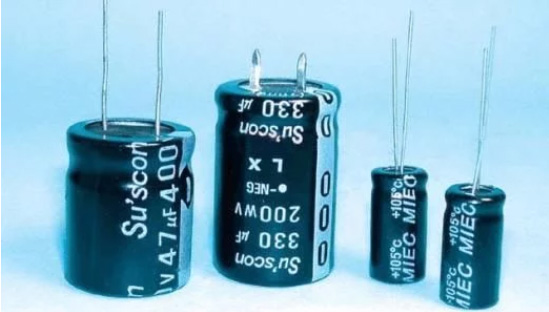

➀Aluminum electrolytic capacitor selection rules

1. In general applications, choose the standard type with a life of 1000HR~3000HR (for price considerations, choose the long-life type carefully), and choose 2000Hr as much as possible for the life of aluminum electrolytic capacitors.

2. For the withstand voltage of aluminum electrolytic capacitors, use 10V for 3.3V systems, 10V for 5V systems, 25V for 12V systems, and 50V for 24V systems; and 100V for systems above 48V.

3. Aluminum electrolytic capacitors must be selected with a working temperature of 105 degrees.

4. For the capacitance value of aluminum electrolytic capacitors, the 10, 22, 47 series are preferred; capacitance models such as 224, 105, and 475 are forbidden under 25V (substituting chip multilayer ceramic capacitors or tantalum electrolytic capacitors).

5. Reserve 400V for high-voltage aluminum electrolytic capacitors. Banned non-polar aluminum electrolytic capacitors.

6. Ordinary aluminum electrolytic capacitors use the brand "SAMWHA" (Sanhe), and high-end aluminum electrolytic capacitors use NCC (Black King Kong) or other Japanese famous aluminum electrolytic capacitors.

7. It is forbidden to use SMD aluminum electrolytic capacitors.

➁Tantalum electrolytic capacitor selection rules

1. Tantalum electrolytic capacitors must not be used with a withstand voltage exceeding 35V.

2. Pin-type tantalum electrolytic capacitors are prohibited.

3. For the withstand voltage of tantalum electrolytic capacitors, use 10V for 3.3V systems, 16V for 5V systems, and 35V for 12V systems. 10V, 16V, and 35V are preferred, and 4V, 6.3V, and 50V are forbidden (use aluminum electrolytic capacitors instead).

4. For the capacitance of tantalum electrolytic capacitors: 10, 22, 47 series are preferred. Tantalum electrolytic capacitors below 105 are banned (replaced with ceramic capacitors).

5. Tantalum electrolytic capacitor brands: KEMET, AVX.

➂ Selection rules for chip multilayer ceramic capacitors

1. Choose high-Q ceramic capacitors carefully; only use in RF circuits.

2. Chip multilayer ceramic capacitor packaging: 0603, 0805 preferred, 1206, 1210 carefully selected, 1808 above banned.

3. The withstand voltage of chip multilayer ceramic capacitors: preferably 25V, 50V, 100V; the withstand voltage of capacitance values above 106 (inclusive) is not more than 25V.

4. Capacitance of chip multilayer ceramic capacitors: 10, 22, 33, 47, 68 series are preferred.

5. The material of chip multilayer ceramic capacitors is preferably NPO, X7R, X5R, others are prohibited.

6. Brands of chip multilayer ceramic capacitors: TAIYO, MURATA, KEMET, TEMEX (high-Q ceramic capacitors).

➃Pin multilayer ceramic capacitor selection rules

1. It is forbidden to use this type of capacitor for new products (use chip multilayer ceramic capacitors instead).

Relay selection rules

1. Brand selection: PANASONIC, OMRON, FINDER.

2. The use of relay sockets is prohibited.

Diode selection rules

1. It is forbidden to use glass-encapsulated diodes.

2. The light-emitting diode is preferably a pin type with a diameter of 5mm. The patch light-emitting diode is preferably a model with a welding frame, and the ESD/MSL level follows the above-mentioned standards.

3. Rectifier diode: The model with the highest back pressure is preferred for the same current level. For example, 1N4007 is used for 1A and IN5408 for 3A.

4. Schottky diode: the highest level of reverse voltage reserved for the same current grade, such as: 1N5819 reserved, 1N5817 banned, SS14 reserved, SS12 banned; M7, 30BQ060, S5G reserved.

5. Light-emitting diodes preferably have sides and short legs; in order to maintain the consistency of the company’s products, red-haired red, green-haired green and other models are preferred, and white-haired red and white-haired green models are selected carefully; if there is no special requirement, try not to use long Feet, boundless.

6. The preferred brand of light-emitting diodes is "Yiguang".

7. The brands of transient suppression diodes are preferably PROTEK and SEMTECH.

Triode selection rules

1. The transistors of the 901X series are 9012 and 9013.

Connector selection rules

1. IC sockets are forbidden. If the use of IC sockets cannot be avoided, IC sockets with round holes must be used.

2. Three-side contact is used for the pin seat, and two-side contact is prohibited. Except PC104 and other special requirements.

3. The complete set of connectors are required to use the same brand, and the plug and socket are required to be of the same brand.

Switch selection rules

1. Disable the DIP switch.

2. The power switch is preferably a rocker switch.

Inductor selection rules

1. The brand of chip inductors prefers "Sanli" and "SUMIDA".

CPU selection rules

1. If the selected CPU is a different model of the same series that our company has used, it needs to be approved by the production payment. If the selected CPU is a new series of CPUs that our company has never used, it must be decided through a meeting with the company-level leaders.

2. Keep Atmega48, Atmega168, Atmega32, Atmega128. New products prohibit the use of attiny2313 and Atmega88.

3. Atmega128 in QFN package is forbidden to be used in future new products.

4. ARM7 can only choose the following: LPC2138FBD64, LPC2292FBD144, STR710FZ2T6, STR711FR2T6.

5. In the future, new products will use COLDFIRE series instead of 68000 series.

FLASH selection rules

1. Parallel FLASH brand prefers SPANSION, SST, and SAMSUNG is prohibited.

2. ATMEL is preferred for serial FLASH brands. New products prohibit the use of AT45DB081B-RI.

SRAM selection rules

Brands prefer ISSI, CYPRESS, MICRON, IDT, and SAMSUNG is disabled.

EEPROM selection rules

1. It is forbidden to use parallel EEPROM.

2. The serial EEPROM brands prefer ATMEL and MICROCHIP.

3. New products are prohibited from using 24LC65-I/SM.

Crystal and crystal selection rules

General technical requirements for crystal materials: AT cut (fundamental frequency), 20pF load capacitance, temperature range -20~+70℃ (industrial temperature grade), manufacturing frequency deviation 30ppm, temperature drift 50ppm/℃, lead-free products.

HOSONIC and EPSON are preferred for crystals and crystal oscillator brands.

Power selection rules

AC/DC selection rules

1. For products with high reliability requirements, the power supply is preferably LAMBDA and COSEL; for products with low reliability requirements, you can choose from Lead Huafu, Xingyuan Fengtai and Mingwei.

2. When choosing the Lambda power supply, it is easy to normalize and requires everyone to choose the model with JST connector.

3. New products try to use standard power supplies, custom power supplies are not recommended.

Isolated DC/DC power supply selection rules

1. Isolation DC/DC power supplies are preferably products of TI. When TI products cannot meet the requirements, C&D is preferred.

Connector selection rules

➀European connector selection rules

1. European connector brands prefer HARTING, ERNI, EPT. The plugs and sockets used in the same set of products require the same brand, and the use of different brands is prohibited.

➁RJ series connector selection rules

1. If it is not necessary to use an external communication signal, it is forbidden to use RJ11 and RJ12 connectors.

2. The RJ45 connecting shrapnel is preferably round pins, with a shielding shell, and the shielding shell has shrapnel. The thickness of the gold-plated layer of the RJ45 connecting shrapnel should not be less than 3uin.

3. It is forbidden to use RJ45 sockets with lights and transformers.

4. The RJ series connector brand is preferably PULSE (FRE).

➂White terminal selection rules

1. Try not to use white terminals.

2. The white terminal brands are preferably JST, AMP, MOLEX.

➃PCB board mounting screw wiring connector selection rules

1. The brand of PCB board mounting screw wiring connector is PHOENIX.

2. The brand of PCB board mounting screw wiring connector is preferably 2-position and 3-position terminal. Connectors with other digits can be spliced using 2-position and 3-position terminal blocks.

3. The pitch of 5.08mm is preferred, and the pitch of 5.00mm is prohibited.

➄Other rectangular connector selection rules

1. The preferred brands of other rectangular connectors are as follows: AMP, MOLEX, SAMTEC, HIROSE, WCON, NSTECH.

2. The thickness of the gold-plated layer of the connector pins should not be less than 3uin.

3. Preferred universal connectors, custom connectors are prohibited.